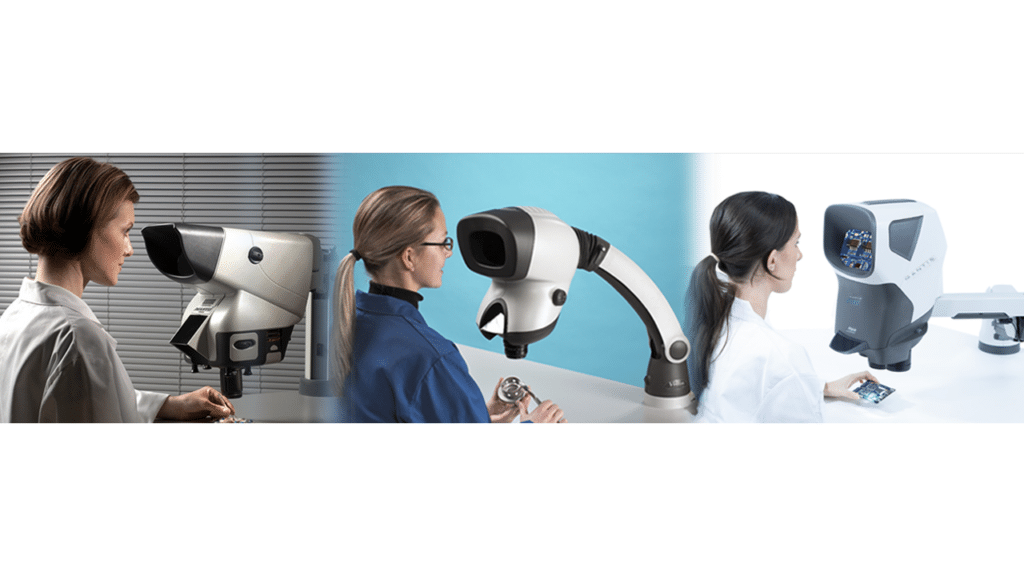

Vision Engineering is celebrating the 30th anniversary of its best-selling and award-winning Mantis range of ergonomic optical stereo microscopes.

In 1994, Vision Engineering introduced the first-ever ‘eyepiece-less’ stereo microscope, Mantis. This instrument was crafted to bridge the gap between a bench magnifier and a traditional microscope, offering users an ergonomic experience.

Its design not only earned Mantis acclaim, but also secured numerous industry-recognised design and innovation awards. As a result, Mantis quickly established itself as the industry standard for high-performance ergonomic stereo magnification, redefining precision and user comfort in industrial microscopy applications within the electronics, medical device, aerospace and automotive industries.

In 2005, Vision Engineering unveiled the second generation of Mantis. Soon after its introduction, Mantis manufacturing moved from Woking to a new manufacturing facility in Connecticut, USA.

This iteration featured notable enhancements, such as a sleek and modern design, improved LED lighting, an expanded field of view, increased magnification capabilities of up to 20x, and stand and accessory options.

In 2009, Vision Engineering expanded the Mantis range by introducing the Mantis Elite HD Cam with a built-in camera for image capture.

The third generation Mantis was introduced in June 2023. The newest edition includes improved optics for both hand-to-eye coordination and excellent depth perception, a 3-position turret to house up to 3 objectives ranging from 3x to 15x, an 8x super long working distance lens, and five different illumination options providing flexibility to optimise the lighting to view the perfect image.

The Mantis PIXO offers an improved, higher-resolution image and ‘designed-in’ integrated video camera. The system also features an option to switch between white and UV light.

Mantis is designed for precision engineering, electronic engineering, medical device manufacture, and a wide range of other applications that require high-quality images and superior ergonomics and is used in tens of thousands of R&D, manufacturing, and analytical sites worldwide.

To read more Vision Engineering news, click here.