Manufacturing

Denrich Sananda, Senior Consultant, Arista Cyber, discusses the link between food safety…

News

SoS was shown the specialized medium to long-range camera offerings from Silent…

News

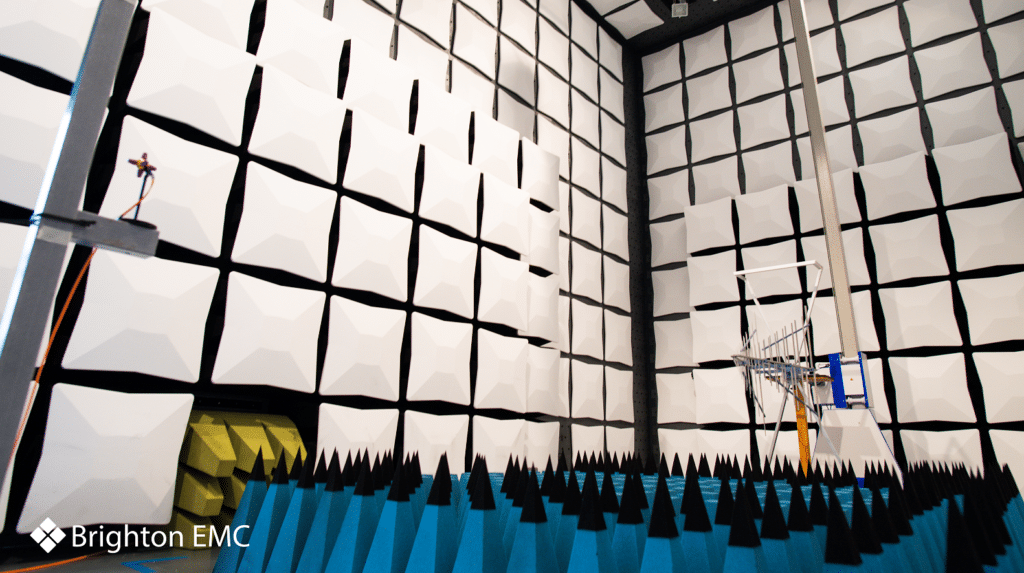

Brighton EMC is the new customer-facing brand for what…

News

Businesses in every sector face the challenge of operating…

News

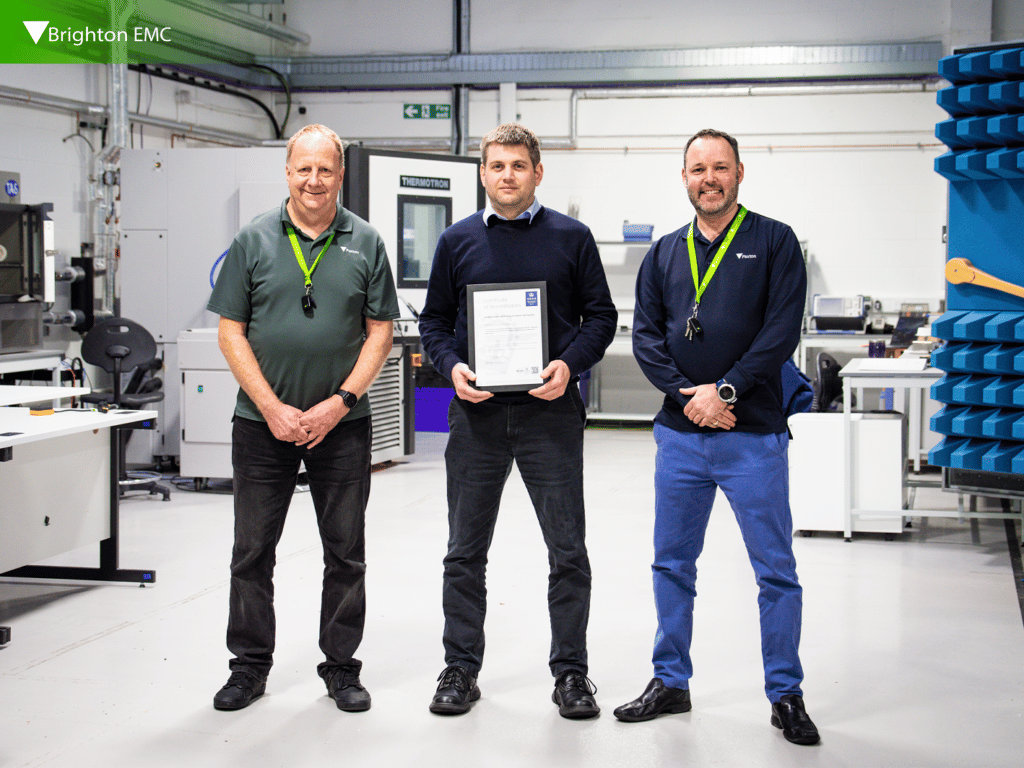

The Sussex-based security technology manufacturer Paxton has gained UKAS…

News

Load More